Have you ever pondered: what is toughened glass? Perhaps you’ve fallen into the trap of believing tempered glass and toughened glass have different uses and you’ve not been sure what’s best for the job. Our handy guide is here to let you have all the facts and help you make the most informed decision for your decorative and architectural glass products.

What’s tempered glass?

Tempered glass and toughened glass are actually the same and Wikipedia defines it best:

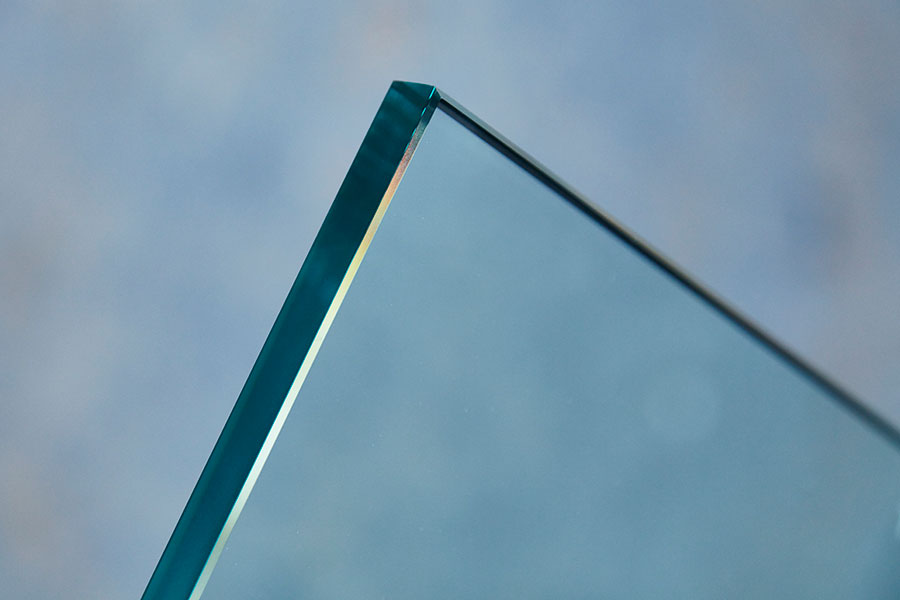

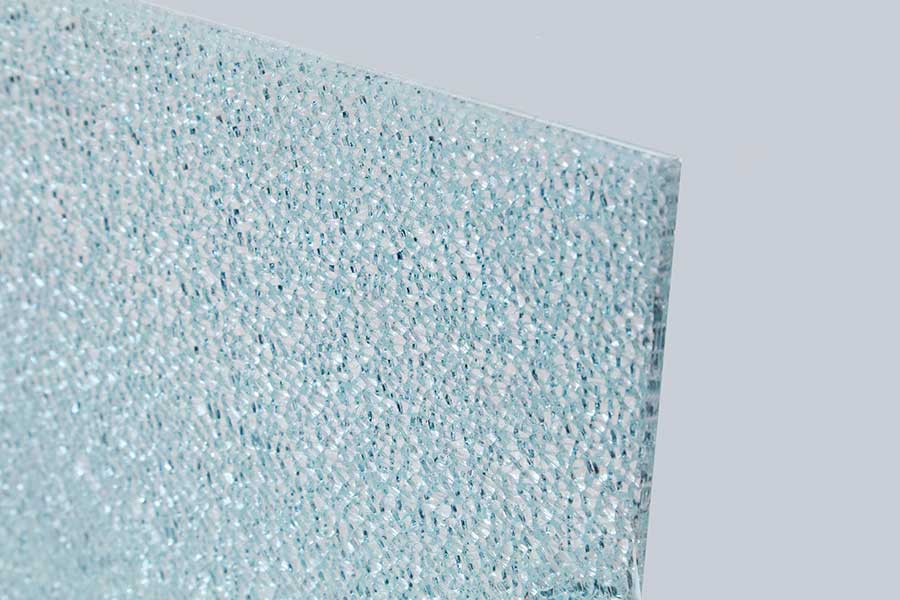

“Tempered or toughened glass is a type of safety glass processed by controlled thermal or chemical treatments to increase its strength compared with normal glass. Tempering puts the outer surfaces into compression and the interior into tension. Such stresses cause the glass, when broken, to crumble into small granular chunks instead of splintering into jagged shards as plate glass (a.k.a. annealed glass) does. The granular chunks are less likely to cause injury”.

Tempered or toughened glass is also as much as 6 times stronger than untreated glass as well as being resistant to impacts. The safety glass credentials come in when tempered/toughened glass is broken into smaller, rounder edged pieces. Whereas normal annealed glass shatters into sharper edged pieces that are much more likely cut the skin on contact.

The safety and strength of tempered glass make it desirable for a variety of architectural and decorative applications in the home and commercial environments. Here at abc Glass Processing, all our high quality glass products are made from tempered/toughened glass as standard – just the way we and our customers like it.

How’s toughened glass made?

Although annealed glass can be transformed into toughened glass via chemical reaction and ion exchange when the glass is immersed in a potassium salt bath at 300°C, abc Glass Processing uses the heat toughening process to create the very best quality tempered glass. Chemically toughened glass is inferior to heat toughened glass because it still breaks into sharp splinters and can’t regarded as safety glass without lamination.

By using our state-of-the-art Glaston toughening furnace, consisting of ceramic rollers that move the glass forward and back, we heat normal annealed glass up to 670°C. The glass is heated for some time (90 seconds to 20 minutes, depending on glass thickness) before it’s chilled back to 15°C so it’s cool enough to touch. The surface of the glass becomes almost molten during the tempering process and is then cooled from the outside in (thinner glass is cooled more rapidly and thicker glass more slowly) using jets of cold air, created by our industrial cooling machine.

The resulting tempered glass is much stronger and more resistant to breakage – under compressive strain on the outside and under tension inside. At abc Glass Processing, the standard of toughened safety glass is self-regulated. This means we break each batch of glass processed to make sure our glass products maintain the highest standards of safety and quality.

How do you know if glass is toughened or tempered?

You can rest assured that all glass products created by abc Glass Processing are created using toughened/tempered glass. On any glass product, you should be able to identify toughened glass by its toughening mark or British/European standard etched into the glass. The exact markings will depend on the toughened glass’ country of origin (where the glass was processed).

Where’s toughened glass used?

Because it’s both super-strong and super-safe, toughened glass is used in a variety of traditional decorative and architectural applications. These might be in the home or commercial settings including the automotive, technological and sports/leisure industries. Applications may include anything from shower doors and fridge trays to mobile screen protectors and diving masks.

At abc Glass Processing, our range of toughened glass architectural and decorative products include, but are not limited to:

- Glass splashbacks

- Mirrors cut to size

- Shower screens

- Glass balustrades & balconies

- Glass staircases & floors

- Glass partitions

- Glass shelves & table tops

Tempered glass also offers thermal resistance and is inherently waterproof. This means it’s an excellent consideration for glass kitchen splashbacks where high temperatures can be reached and glass bathroom splashbacks where high humidity is common. Likewise, glass is ideal for frameless glass doors and wall partitions inside the home as well as glass doors and windows outside the home, which need to offer greater protection from the elements and could be liable to stress from excessive banging and impacts.

Can toughened glass be cut?

Yes, your toughened glass for shower enclosures, balustrades, splashbacks or any other application can be cut to any size and shape you require. Cutting tempered glass, however, happens before the glass toughening process so it’s easier and more precise. Really, annealed glass is cut and then toughened or tempered.

Why does tempered (or toughened) glass break?

Let’s face it, most things have a breaking point but the toughening of glass does make it harder to break than untoughened glass. As well as thermal stresses within the glass, damage during installation – such as a chipped edge developing into a larger break – is the most common cause of breakage. When it does break, tempered/toughened glass is designed to shatter into small pieces that are much less likely to cause injury. This is why toughened glass is often referred to as “safety glass”.

How can toughened glass break?

As already mentioned, while toughened glass is stronger than standard glass and will be harder to break it can still be broken. The difference is that toughened glass is designed to shatter, breaking into lots of very small pieces. While it’s still possible that these pieces will cause minor cuts, they’re too small and dull to cause serious harm. Glass that’s not toughened will break into large shards, which will be very sharp and dangerous – not ideal for any domestic or commercial application if you want to keep your family or clients safe!

Find out more about our toughened safety glass

For more information about our professional glass processing services, quality toughened glass for glass splashbacks or toughened glass mirrors cut to size, get in touch with Hampshire glass processing experts abc.