Have you ever looked at an impressive window or a piece of glass furniture and wondered: how is glass made? For a material so widespread, few people who know the ins and outs of making glass. In this article, we’ll lay out the basics of glassmaking so that you can appreciate the subtleties of this incredible material. We’ll also answer some of the most frequently asked questions about glass, from the common to the obscure.

What is glass made of?

A lot of people ask us: Is glass made from sand? This is half-right – the raw material of glass is in fact made from three ingredients: sand, limestone and soda ash. In order to make glass, these three ingredients must be mixed together and heated in a giant furnace. Eventually, the mixture melts into a liquid called glass. That’s right: glass is actually a liquid!

To be clear, when we say “heated in a furnace”, we’re talking about serious heat. For liquid glass to form properly, the furnace temperature must be at least 1700°C (3090°F). Anything below this extreme heat level may be inadequate for making glass. Needless to say, unlike brewing beer or weaving fabrics, glassmaking is not something that can be done at home.

How does liquid glass become solid?

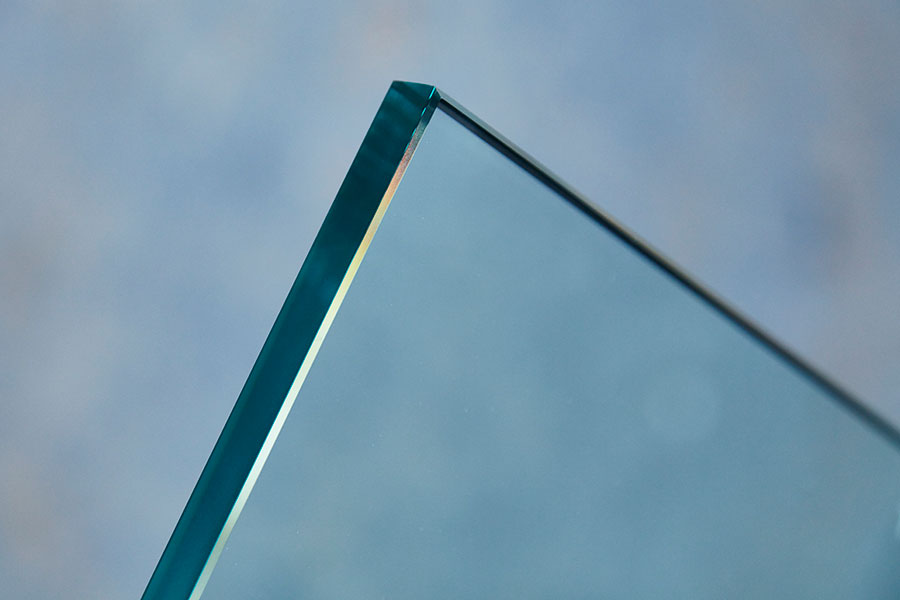

At abc Glass Processing, we typically use large sheets of float glass or plate glass that can be easily cut or shaped. This is raw, unprocessed or toughened glass in its basic form – the kind that, if you smash it, breaks into large pieces. So far we’ve explained how glass is formed as a liquid mixture, but how does it turn into the flat, solid sheets that we commonly call “glass”?

There are two basic ways to make plate glass: rolling and floating. Both require the liquid glass to be cooled until it forms into a flat, solid material. The former method uses giant rollers to flatten the glass into thin sheets, which are left to cool before being cut into the desired shape. The latter way involves leaving the scorching-hot liquid to “float” on top of molten tin until it reaches a much lower temperature. The end result is an immaculate, flat sheet of solid glass.

Is glass recyclable?

Of course! Glass is among the most recyclable materials in the world, able to be re-used and re-processed over and over again. Recycled glass makes up a remarkable 95% of the raw materials of most new glass product. The more recycled glass used in the manufacturing process, the less energy is used by furnaces. This efficiency makes glass production one of the more sustainable industries in the modern world. So, if you want to help the planet through these challenging times, make sure you recycle those glass bottles!

Some popular uses for recycled glass

- Making new glass products

- Fibreglass insulation products

- Manufacturing of bricks where glass is used as a flux

- Astroturf and artificial grass products

- Water filtration media

- Reflective paints

- Sandpaper and other abrasive materials

Each year abc Glass processing recycle around 120 tonnes of glass.

At abc Glass Processing, our team boasts years of experience in processing glass for all manner of commercial and domestic uses. Click here to explore our many glass processing services, or get in touch today if you have any questions about a potential project.